Innovations

In recent years there has been an argument for reversing global warming. The belief is that people must significantly reduce and then eliminate greenhouse gas emissions by transitioning to renewable energy, increasing energy efficiency, adopting sustainable transportation and agriculture, and improving forest and waste management.

The primary reason for doing so is to mitigate devastating impacts on the planet, including rising temperatures, altered rainfall, coastal erosion, and threats to ecosystems and human well-being, ultimately preventing the catastrophic consequences of a continually warming Earth.

In the war for the future and a livable environment, carbon removal is apparently essential for meeting global climate goals. Removing historical and hard-to-abate emissions that remain in the atmosphere for centuries, like CO2, would help slow and potentially reverse climate change.

CO2‘s very high chemical stability is at the root of this persistence effect. Due to the inertia of CO2 in the atmosphere, climate change will continue to increase for decades, centuries or millennia if nothing is done. Since excess CO2 in the atmosphere is the primary driver of climate change, so removal of CO2 could potentially reverse global warming. Carbon removal attempts to abate this problem by absorbing carbon from the environment.

Why carbon removal systems?

If people suddenly stopped emitting greenhouse gases on a global scale, 40% of the surplus CO2 created would still be in the atmosphere a century later, and 20% would still be there after 1,000 years.

Carbon removal facilities employ various technologies and natural processes, including large machines for Direct Air Capture (DAC) and methods like afforestation (planting new forests) and the cultivation of seaweed. The goal is to reduce the overall concentration of CO2, which is a significant driver of climate change.

Success projections for carbon removal facilities are mixed, with analysts suggesting they are not a cure but could play a crucial role in mitigating climate change alongside major emission cuts. Engineered removal methods like Direct Air Capture (DAC) and industrial carbon capture face significant hurdles, including high costs, massive energy demands, and scalability challenges. For these facilities to have a meaningful environmental impact, they would require a massive scale-up over the next few decades, the viability of which depends on sustained innovation, policy support, and investment.

Carbon removal facilities are diverse, falling into nature-based, engineered, and hybrid categories. Hybrid approaches combine these, such as biochar production and enhanced mineralization.

What IT Do

Carbon removal facilities work typically by capturing carbon dioxide (CO2) from the atmosphere or industrial sources using chemical processes and then storing it underground in geological formations or repurposing it for other uses.

How Carbon Removal Works

Carbon removal encompasses two primary approaches and one secondary approach:

Natural Solutions include creating and conserving natural carbon sinks, such as forests, that absorb and store carbon. Soil carbon sequestration is another natural process, though it has natural limits. The following methods leverage natural processes to capture and store carbon:

Afforestation/Reforestation: Planting new forests or allowing existing ones to regrow, creating more trees to absorb CO2 through photosynthesis.

Soil Carbon Sequestration: Implementing agricultural practices like no-till farming to increase the amount of carbon stored in the soil.

Ocean-based CDR: Methods like ocean fertilization, ocean alkalinity enhancement, and restoring blue carbon ecosystems (like mangroves and seagrasses) to absorb carbon from the sea.

Technological Solutions involve direct technological processes such as DAC, which removes CO₂ from the air, and Bioenergy with Carbon Capture and Storage (BECCS), which captures carbon from plants used for energy production and stores it underground.

These methods use technology to capture and store carbon:

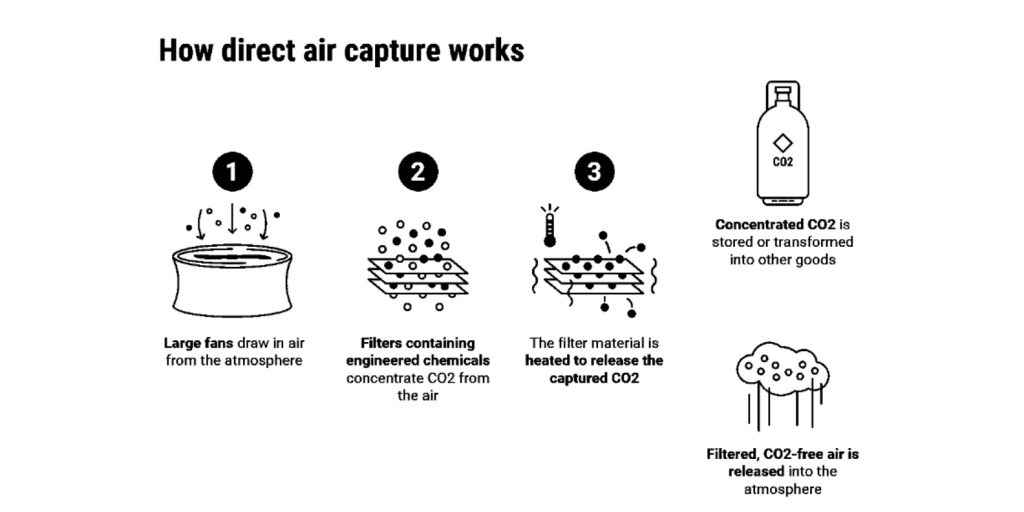

Direct Air Capture (DAC): Machines with large fans that funnel air through chemical processes to pull out and then store carbon dioxide.

Bioenergy with Carbon Capture and Storage (BECCS): Growing biomass (like wood), burning it to produce energy, and then capturing the CO2 from the combustion process for storage.

Carbon Capture and Storage (CCS): Capturing CO2 directly from industrial emissions and storing it in underground geological formations.

Carbon Mineralization: Using specific minerals to react with CO2, chemically binding it into a stable solid form.

Hybrid Solutions blend natural and technological components and consist of the following:

Biochar: A form of charcoal created by heating biomass at high temperatures with low oxygen. It can then be incorporated into soil to store carbon and improve soil quality.

Enhanced Weathering: Spreading crushed rocks across land to accelerate the natural process of minerals absorbing CO2 from the atmosphere.

Hybrid carbon removal offers co-benefits such as mitigating ocean acidification, improving ecosystems, and enhancing food security by restoring natural processes and integrating technological solutions like Direct Air Capture (DAC) and Bioenergy with Carbon Capture and Storage (BECCS)

How IT Do IT

Bioenergy with Carbon Capture and Storage

BECCS stands for Bioenergy with Carbon Capture and Storage, a carbon dioxide removal (CDR) technology that aims to achieve net negative emissions by capturing CO2 emissions from the combustion or conversion of biomass (like wood or agricultural waste) and then storing that carbon in geological formations.

While BECCS holds potential for removing carbon from the atmosphere, its large-scale implementation faces significant challenges and uncertainties, including the sustainability of biomass sourcing, the reliability of long-term carbon storage, and potential negative impacts on land use and ecosystems.

How BECCS Works

1. Bioenergy Production: Plants and trees absorb CO2 from the atmosphere as they grow. This biomass is then used to generate heat, electricity, or biofuels.

2. Carbon Capture: During the bioenergy conversion process, the resulting CO2 emissions are captured.

3. Carbon Storage: The captured CO2 is then transported and stored in underground geological formations or used in long-lasting products.

Biochar

Biochar pyrolysis is the process of converting biomass into a charcoal-like material called biochar by heating it in a low or no-oxygen environment. This thermo-chemical process also produces other byproducts, including bio-oil and syngas. Biochar is primarily used to improve soil fertility by enhancing water retention and nutrient availability, but it also offers benefits like carbon sequestration.

Biochar is often “activated” before use by mixing it with compost or other organic matter to encourage microbial colonization. It can be incorporated into the soil during planting or added to existing beds.Biochar can also be added to compost piles to enhance the composting process.

Process integration involve methods that integrate processes, such as placing biochar pyrolysis close to calcination, to facilitate the production of durable materials like “green cement” or to capture and reuse thermal energy.

Operational Methods and Technologies

Sensor-based adaptability systems can use sensors to trigger conditional responses, such as separating different biochar production runs to protect them from risks or adjusting operation in response to environmental factors like hot, dry, or rainy conditions, as noted in the Orca DAC plant.

Production protocol switching is where a facility can switch between operating protocols to prioritize different goals, such as maximizing power generation or preventing the shortage of a particular biochar product.

Direct Air Capture (DAC)

- How it works: Large-scale fans pull ambient air through a capture station.

- Separation: Inside the station, chemical reactions cause the CO2 to separate from the other gases in the air.

- Storage: The concentrated CO2 is then compressed and stored deep underground, where it reacts with minerals to form stable rock, or it can be used by industries.

Industrial Post-Combustion Carbon Capture

Combustion Carbon Capture refers to methods of separating and removing CO2 from the exhaust gases produced when fossil fuels are burned

- How it works: This is a common technique used for power plants. The CO2-rich flue gas is diverted and passed through a liquid solvent, such as monoethanol amine.

- Absorption: The solvent absorbs the CO2.

- Regeneration: The CO2-rich solvent is heated, which releases the CO2.

- Compression: The released CO2 is then cooled and compressed for transport and storage.

Enhanced Mineralization or Weathering

Enhanced mineralization, or enhanced weathering, is a carbon removal technique that accelerates the natural process where rocks, particularly those rich in calcium and magnesium, absorb atmospheric CO2 and convert it into stable carbonate mineral. Adding minerals, such as ground basalt rock, to soils can increase the ocean’s natural capacity to absorb and store carbon.

Another method leverages photosynthesis in coastal plants, seaweed, or phytoplankton by adding certain minerals to seawater that react with dissolved CO2 and lock it away or running an electric current through seawater to accelerate reactions that ultimately help extract CO2.

Carbon Removal Initiatives In Action

The Archer Daniels Midland (ADM) Illinois Carbon Removal Facility in Decatur, Illinois, is a project that captures CO₂ from ADM’s ethanol plant and permanently stores it underground. It was the first large-scale industrial facility in the U.S. to permanently store CO₂ underground using Class VI injection wells in a deep sandstone formation. The facility includes a CO₂ compression and dehydration unit, an injection wellhead, and monitoring infrastructure to ensure the CO₂ remains sequestered.

Key Features of the Facility

Purpose:To demonstrate and implement large-scale carbon capture and storage (CCS) technology for industrial CO₂ emissions.

Location: The facility is located in Decatur, Illinois, at ADM’s ethanol production plant.

Process: CO₂ is captured from ADM’s corn-to-ethanol processes. The captured CO₂ is then compressed and dehydrated at the facility. Finally, the CO₂ is injected deep underground, hundreds of feet below the surface, into a saltwater-saturated sandstone formation.

Significance:It serves as a model and early example of how CCS technology can be applied to industrial facilities and is a pioneering project for commercial-scale saline storage.

Context Responsive Systems for Carbon Removal

Examples and Developing Innovations

Direct Air Capture (DAC) Plants: The Orca DAC plant in Iceland uses fans to draw air through sorbent-coated collectors, which are then heated to release concentrated CO2. The plant adapts its operation to various weather conditions, highlighting the need for context-responsive systems.

Biochar and Biomass Conversion: Methods like biochar production and bioenergy with carbon capture and storage (BECCS) are being developed as carbon removal facilities.

Carbon Neutrality and Technology Companies

Many companies are adopting various strategies to become carbon neutral, including investing in renewable energy, improving energy efficiency, electrifying fleets, implementing circular economy practices like recycling, investing in carbon removal projects such as reforestation, and using carbon offsetting for unavoidable emissions.

Companies want to be carbon neutral for various reasons, such as improving their reputation, attracting investors and impressing customers who prioritize sustainability. Also, reductions in operational costs by investing in energy efficiency, mitigating future risks from climate regulations, and to demonstrating corporate responsibility for the environment can also provide a competitive advantage. It helps companies future-proof their business and appeal to a growing market of eco-conscious consumers and employees.

Environmental Co-Benefits and Challenges

Beyond climate mitigation, carbon removal can lead to improved soil health, enhanced coastal ecosystems, increased biodiversity, and better food production. Tech companies are already implementing carbon neutral strategies. Apple uses renewables and encourages supplier participation, Microsoft focuses on energy efficiency and carbon removal, and Google operates on carbon-free energy and promotes recycling.

For the rest of the industrial landscape, the high investment costs required for transitioning to a carbon-neutral economy is enormous. This is a major barrier for both companies and governments, especially in developing nations. Economic disruption could cause major economic shifts, including job displacement in fossil fuel industries and changes to existing business models. These disruptions can create political and social resistance to climate action.

Offsetting risks and uncertainties demands the integrity of carbon offsetting. However, this is loaded with issues like double counting, non-additivity (taking credit for emissions reductions that would have happened anyway), and permanence (e.g., a protected forest later being destroyed). Rigorous environmental standards and public confidence are essential for the responsible deployment of these new technologies. For more information about biochar and other carbon removal methods, reference the links below.

Net Zero Coalition for the United Nations

International Biochar Initiative

Codes used to classify businesses by industry for data collection and analysis for Carbon Removal Outfits

SIC Codes

8711-039 – Environmental Engineers & Engineering Services

8748-002 – Environmental Consultants

NAICS Codes

541620 – Environmental Consulting Services

562211 – Hazardous Waste Treatment and Disposal

562219 – Other Nonhazardous Waste Treatment and Disposal

Leave a reply to webmasterfh Cancel reply